3D printing has revolutionised the manufacturing industry, by providing cost-effective solutions for prototyping, reverse engineering, and low-volume production. 3D printing services, whether it be Fused Deposition Modeling (FDM) , Digital Light Processing (DLP), Multi-Jet Fusion or one of the many available technologies, stand out for affordability, material versatility, and rapid turnaround times.

At Profin H.D. we constantly use 3d printing to assist our customers and the technology is nothing short of priceless in terms of what it brings to the table.

In this article, we explore how 3D printing can be leveraged for industrial applications, specifically for prototyping and reverse engineering, and discuss the advantages and limitations of widely available materials.

Cost-Effective Prototyping with 3D Printing Services

One of the most significant industrial applications of 3D printing is rapid prototyping. Traditionally, creating a prototype using CNC machining or injection molding can be time-consuming and costly, especially when you factor in multiple iterations. When milling a part, especially if you have machinable geometry on each side of the part you need to create one or more fixtures to flip the part and machine the other side(s) when using a conventional 3 axis milling machine or possibly even when using a 4th axis.

There are of course 5 axis milling machines that can help minimise the need for fixturing but such machines are expensive to buy and program, driving up the cost and lead time of producing a one off dramatically. This is where 3d printing services can save you serious amounts of time and money.

3D printing allows engineers and manufacturers to produce functional prototypes quickly and affordably, enabling them to test fit, function, and design iterations with minimal investment.

By using 3D printing services for prototyping, companies can:

- Reduce lead times from weeks to days – programming a 3d printer is significantly quicker than a C.N.C. machine, stock/material is typically held in spools of filament, liquid or powder, so there is no need to order in stock to the correct dimensions.

- Identify design flaws early in development. Often even if you have created a 3D assembly in C.A.D. it can be much easier to identify assembly or fitment issues when you are holding a 3d model in your hand.

- Test multiple iterations without high tooling costs. 3D printing does not require fixturing to create geometry on every side of the part and as a result far less planning.

- Create difficult or even impossible to machine geometries .

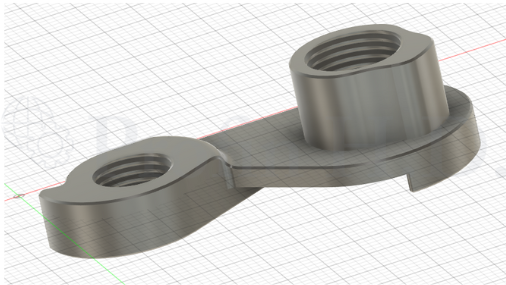

Example – Bicycle Rear Mech Hanger

In this example we were asked to machine a batch of rear mech hangers for a well known Italian bicycle frame by a retailer. During the COVID lockdown there was a boom in terms of demand for bicycles and parts, but the catch was a lack of availability. Naturally the retailer only had a sample to work from, no 3d model and no drawing.

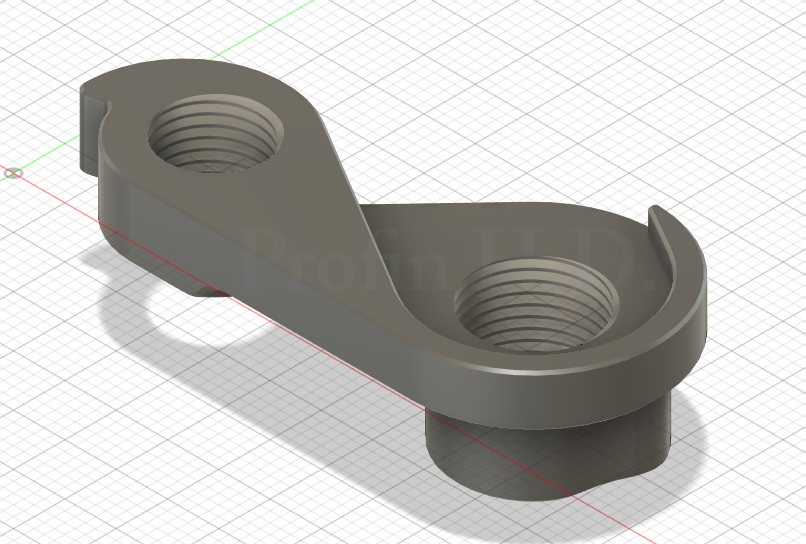

Now in terms of geometry this part is all curves (which makes establishing 1 datum difficult) and the fit in the frame was a very snug “push fit”. The plan was to machine this part in 2 operations. The first operation just from the raw stock held in a vise, the second in a pallet style fixture that could hold 20 parts per time accurately, using the geometry machined in the first op.

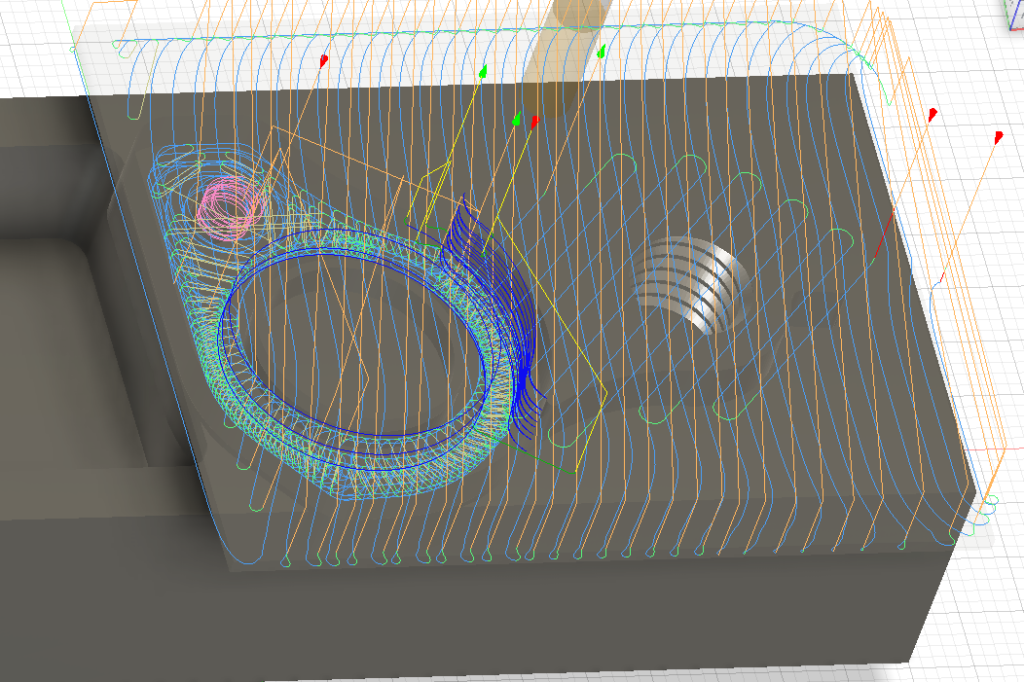

Making this fixture takes time, effort and money. You have to design the fixture, generate the tool paths to machine the fixture and then generate the tool paths to machine the actual part. In short many hours, maybe even running into a couple of days. Here is an example of a small fixture (below) with the tool paths showing for op 2 of another rear mech hanger.

So, if the part spec was wrong such a mistake would put production back days and increase costs and this is where 3d printing services can reduce the amount of commitment required. Firstly a 3d model was created by Profin H.D. for our client as shown above. Next we 3d printed the part using a high resolution DLP printer as shown below – in the bottom left you can see the 3d print next to the original sample and in the top left how the 3d printed part blends with the frame’s geometry.

As you can see above we have two very different approaches. We can either:

- Machine our model having designed and machined a fixture, programmed the tool paths, purchased the stock in relevant dimensions, cut the stock to size, cleaned up the swarf etc. and potentially having to repeat the process to revise the part. Assuming the part is correct the first time we will have still spent hours creating a prototype, or…

- Import the 3d file into a slicing software and have a prototype within a couple of hours having spent just minutes in labour time and pennies in material to create it. In fact we could produce multiple iterations in just one day with a very small investment of time and material.

3d printing services enable us to offer our clients competitive quotes for prototyping and revisions. In this case the client pushed forward and asked us to machine those parts in aluminium, here is the finished result a much nicer finish than the original sample and at a lower cost than OEM.

Reverse Engineering for Cost Reduction

3D printing also plays a crucial role in reverse engineering. Whether a part is obsolete, expensive to machine, or requires modifications, 3D scanning and FDM printing can be used to create accurate replicas and enhanced designs.

Industries such as automotive, aerospace, and manufacturing benefit from reverse engineering by:

- Recreating out-of-production parts.

- Reducing material waste compared to traditional machining.

- Modifying existing components for improved performance.

- Lowering costs of replacement parts.

Engineers can quickly reproduce complex geometries and improve designs while maintaining cost efficiency by utilising 3d printing services.

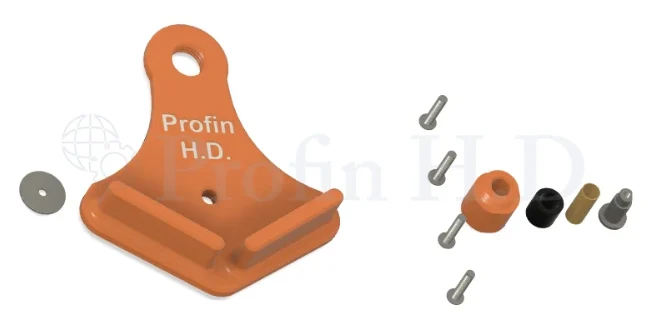

Example – Machinery Part from a Paper Manufacturer, 3d printing services for production.

In this case study we were approached by a toilet paper manufacturer to make a part for their machine on their production line. When both layers of toilet paper are laminated together and rolled onto a brown core the product is made into a two meter length of toilet roll (known as a log) before it is sent through a machine to be sliced up into individual rolls. These logs are held in cradles and at each end of the cradle the manufacturer had the aluminium part below.

This part was had a number of problems:

- It was expensive to fabricate, each one was being cut by hand and then welded together (not all welders can weld aluminium).

- The lead time on an order for the parts was long as they were labour intensive.

- It was effectively disposable, the welded aluminium boss you can see below would eventually wear out but because the part was welded together it had to be scrapped.

- It was too strong, if a “log” became dislodged from the cradle it could tangle in the machine and cause a jam, damaging the machine. Ideally the customer wanted the cradle ends to fail/snap rather than damaging the machine.

We proposed a 3d printed solution to the customer which had the following advantages:

- The cost of producing the complete assembly, including all machined parts was just 18% of the cost of the aluminium part.

- We could produce 64 complete assemblies per day using our print farm versus a maximum of 10 per day with the aluminium part from another supplier.

- The 3d printed part was modular. Instead of the aluminium boss, a brass sleeve was pressed into a threaded 3d printed part. This small and inexpensive boss with a brass sleeve could be replaced, rather than having to replace the entire assembly.

- We deliberately made a small stress riser in the part so it would snap at the weakest point if the machine jammed and in doing so prevent costly repairs and machine down time.

The customer initially ordered 2 test samples but once those samples had proved their performance several large batches were made over the next few years, they are still in service to this day.

Common FDM 3D Printing Materials and Their Properties

FDM 3D printing supports a wide range of materials, each with unique mechanical properties suited for different industrial applications. Below is an overview of commonly used materials, their benefits, and potential drawbacks:

1. PLA (Polylactic Acid)

- Pros: Biodegradable, easy to print, low cost, good tensile strength (~60 MPa)

- Cons: Brittle, low temperature resistance (~60°C), poor impact resistance

- Best Uses: Concept models, non-functional prototypes, aesthetic parts

2. ABS (Acrylonitrile Butadiene Styrene)

- Pros: Higher strength (~40-50 MPa), better impact resistance than PLA, temperature resistance (~105°C)

- Cons: Prone to warping, requires a heated bed, moderate chemical resistance

- Best Uses: Functional prototypes, automotive parts, enclosures

3. PETG (Polyethylene Terephthalate Glycol-Modified)

- Pros: Strong (~50 MPa), good flexibility, chemical and water resistance, temperature resistance (~75°C)

- Cons: Can be stringy during printing, slightly less rigid than ABS

- Best Uses: Food-safe applications, mechanical parts, outdoor components

4. Nylon

- Pros: High tensile (~70 MPa) and flexural strength, impact resistant, good wear resistance

- Cons: Absorbs moisture (requires dry storage), difficult to print due to warping

- Best Uses: Gears, bushings, industrial fixtures, durable prototypes

5. Carbon Fiber-Reinforced Filaments (PLA, ABS, Nylon blends)

- Pros: Increased stiffness, lightweight, excellent strength-to-weight ratio

- Cons: Brittle, requires hardened nozzle, more expensive than standard filaments

- Best Uses: Aerospace, automotive, structural parts requiring high stiffness

6. Polycarbonate (PC)

- Pros: High heat resistance (~120°C), superior impact strength (~70-90 MPa)

- Cons: Requires high printing temperatures, warping issues, prone to moisture absorption

- Best Uses: Industrial tooling, high-strength mechanical components, protective enclosures

Common DLP Materials and Their Properties

Digital Light Processing (DLP) excels at smaller higher accuracy parts. Using this technology the printer uses ultra violent light to cure resin into a 3d part 1 layer at a time. One major advantage with this technology is that it doesn’t matter whether you are making 1 part or 100, the print time is the same. This is because the printer “flashes” an entire layer at a time using it’s UV projection screen, whereas FDM printers need to move the printhead across 1 part at a time. Another advantage is that DLP printers can create very detailed and accurate parts (moreso than FDM) as the pixel resolution of the screen is very high, figures of 53, 35 and 22 microns are very common.

DLP printer resins aren’t quite as straightforward as raw material for machining or even FDM printer materials, there just isn’t the same level of standardisation. For example if you buy 6082 aluminium you know exactly what you are getting, with DLP the quality and list of pros/cons can vary wildly. However here are some notable options that we really like:

- Evonik’s INFINAM® ST 6100 L: This high-strength photopolymer boasts a tensile strength of 89 MPa, making it suitable for applications demanding both high mechanical strength and temperature resistance.

- ETEC’s E-RigidForm: A polyurethane-like resin with a tensile strength ranging between 68 to 73 MPa, ideal for producing strong, stiff end-use parts.

- Henkel’s LOCTITE® IND405: A high-strength engineering plastic with a tensile strength of 45 MPa, suitable for end-use parts and tooling.

- Photocentric’s High Tensile UV: Designed for objects requiring high tensile strength and hardness, this resin achieves an ultimate tensile strength of 57.8 MPa.

- Liqcreate’s Strong-X: One of the strongest photopolymer resins available, it boasts a flexural strength of 135 MPa, making it ideal for injection molding and heavy-duty applications. It has a milky white finish

- Liqcreate’s Tough-X: An opaque black photopolymer with exceptional impact strength and up to 150% elongation, excellent for some industrial spare parts and functional products, although it is quite flexible (a trade off for the impact resistance).

- Liqcreate’s Flexible-X: An opaque black photopolymer resin with a low hardness of 55 Shore A and elongation up to 160%, suitable for manufacturing soft touch and elastic parts for industrial use.

These materials exemplify the advancements in DLP 3D printing, enabling the production of parts with tailored mechanical properties for various industrial applications.

Conclusion

FDM 3D printing provides manufacturers with a versatile and cost-effective solution for industrial applications such as prototyping and reverse engineering. By selecting the appropriate material, industries can optimize their production process, reduce costs, and improve efficiency. With the continual advancements in material science and 3D printing technology, the applications of FDM printing in industrial manufacturing will only continue to grow.

If you would like to discuss 3d printing services with us please get in touch or book a consultation.

Contact Us